When you see a crane effortlessly lifting massive steel beams or heavy machinery hundreds of feet into the air, have you ever wondered what gives it the strength to handle such immense loads? The answer lies in a critical component: the hoist wire rope.

This unassuming piece of equipment is the literal lifeline of any crane operation. Its failure is not an option. Therefore, the material it's made from is chosen with extreme care to balance strength, flexibility, durability, and cost.

So, which material is the undisputed champion for crane hoist wire ropes?

The answer is: High-Carbon Steel.

Specifically, crane hoist ropes are made from cold-drawn, high-carbon steel wire. This isn't your everyday steel; it's a material engineered for peak performance under staggering stress.

Why High-Carbon Steel? The Winning Properties

High-carbon steel is chosen because it delivers a perfect combination of the essential properties needed for safe and efficient lifting:

- Exceptional Strength (High Tensile Strength):

- The primary job of a wire rope is to support weight without breaking. The addition of carbon to steel significantly increases its tensile strength. These ropes have tensile strengths typically ranging from 1,770 MPa to 2,160 MPa (or even higher), which is often classified as "Improved Plow Steel" (IPS) or "Extra Improved Plow Steel" (EIPS). This means a relatively thin wire rope can safely hold an enormous amount of weight.

- Excellent Fatigue Resistance:

- A crane rope doesn't just hold a static load. It constantly bends over sheaves and drums, is subjected to shock loads, and endures countless cycles of tension and relaxation. High-carbon steel, through the drawing process, has a fine-grained structure that resists the initiation and growth of cracks caused by this repeated bending and flexing.

- Good Wear Resistance:

- As the rope runs over drums and through sheaves, individual wires experience friction—both internally and with the equipment. The hard surface of high-carbon steel provides resistance against this abrasive wear, which helps extend the rope's service life.

- Toughness:

- While being hard and strong, the rope must also have a degree of toughness to absorb energy and withstand impact loads (e.g., the sudden taking up of a slack rope) without becoming brittle and snapping.

Not Just Steel: The Role of Coatings

While the core material is high-carbon steel, the wires are often further enhanced with protective coatings to combat their greatest enemy: corrosion.

- Galvanization (Zinc Coating): This is the most common protective treatment. Galvanized wire ropes are essential for cranes working in environments where moisture and corrosion are concerns, such as:

- Marine and offshore applications

- Chemical plants

- Outdoor storage yards in humid climates

- Galvanization significantly extends rope life by sacrificing the zinc coating to protect the underlying steel.

- Bright (Uncoated) Steel: Used in indoor applications or environments where corrosion is not a significant factor. Bright ropes are typically the most economical option but require careful inspection and maintenance if conditions change.

- Other Coatings: For extreme environments, specialty coatings like stainless steel (for highly corrosive atmospheres) or polymer coatings can be used, though they are less common for standard crane hoisting due to cost and specific property trade-offs.

Construction: More Than Just Material

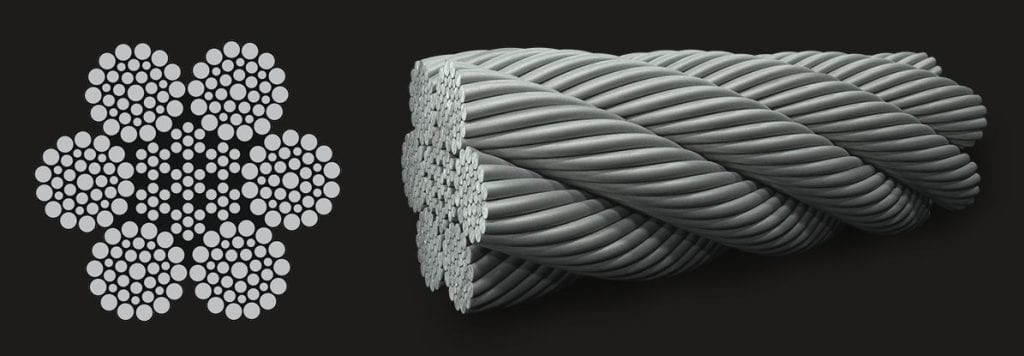

It's also important to note that the material is only half the story. The construction of the rope—how the individual wires are laid into strands and how those strands are laid around a core—is equally critical. The most common construction for crane hoists is a 6x36 or 6x19 class rope with a fiber core (FC) or independent wire rope core (IWRC), which provides an optimal balance of flexibility and strength.

Conclusion

The next time you witness a crane in action, remember the marvel of engineering in its hoist rope. It’s not just a simple cable; it’s a complex assembly of high-carbon steel wires, meticulously crafted and often protected with zinc, designed to provide the incredible strength and reliability that modern construction and industry rely on every day. The choice of material is no accident—it’s the result of over a century of refinement to ensure safety and performance at the limits of what’s possible.